Sustainable Materials in Vehicle Manufacturing Advancements

The automotive industry is undergoing a significant transformation, with a growing emphasis on sustainability across all stages of vehicle manufacturing. This shift is driven by environmental concerns, regulatory pressures, and consumer demand for more eco-friendly products. Innovations in material science are at the forefront of this evolution, paving the way for vehicles that are not only more efficient and safer but also have a reduced environmental footprint from production to end-of-life. Exploring these advancements reveals a future where vehicle components are increasingly sourced from renewable, recycled, or low-impact materials, redefining the standards for modern transport.

The Drive Towards Sustainable Automotive Materials

The push for sustainable practices in the automotive sector is reshaping how vehicles are designed and produced. Manufacturers are actively seeking alternatives to traditional materials, focusing on options that minimize resource depletion, reduce energy consumption during production, and are easier to recycle. This includes the development of bio-based composites, recycled plastics, and lightweight alloys, all contributing to a more circular economy within automotive manufacturing. The integration of these materials is crucial for meeting global sustainability targets and enhancing the overall environmental performance of the transport sector.

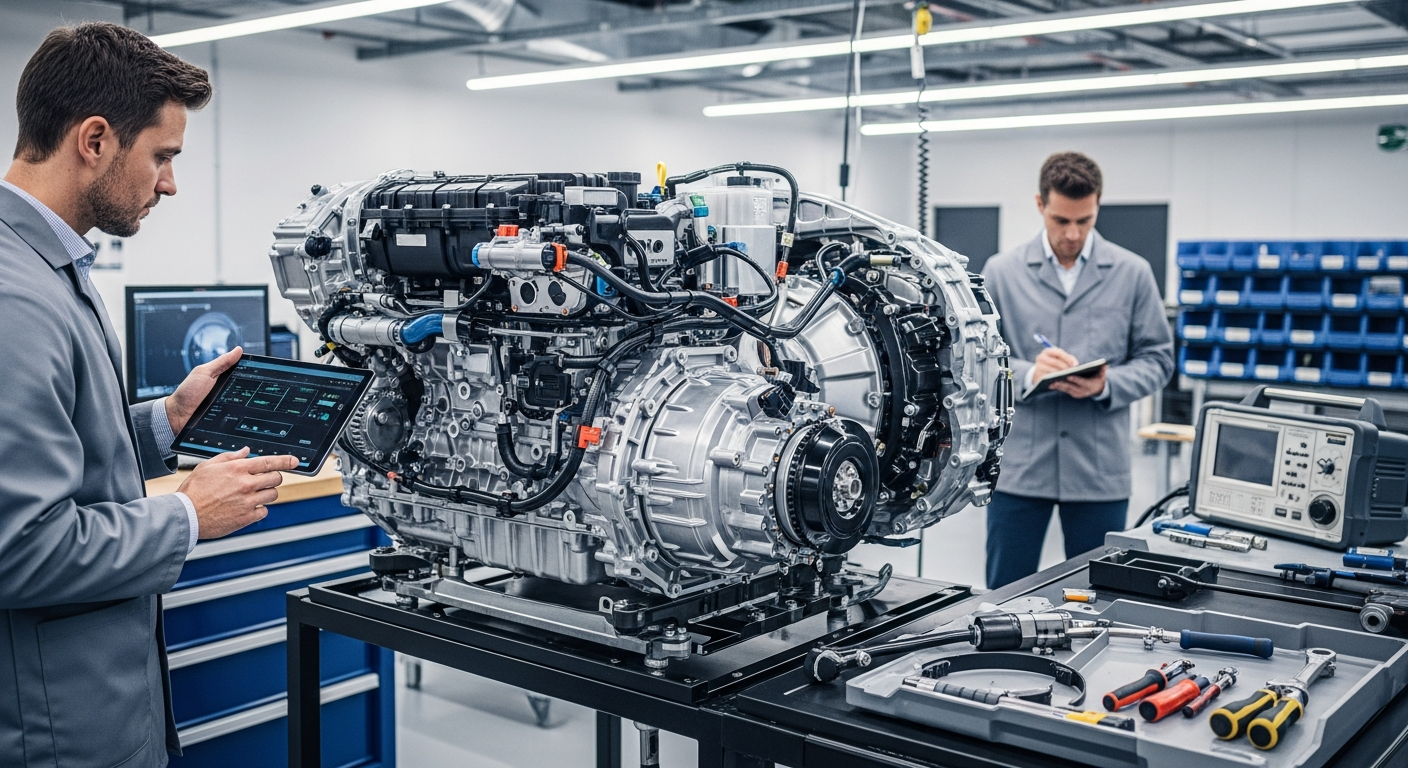

Innovations in Electric Vehicle and Mobility Components

The rise of electric vehicles (EVs) and new mobility solutions has accelerated the demand for specialized sustainable materials. Battery technology, a core component of electric vehicles, is seeing advancements in material composition to improve energy density and reduce reliance on rare earth elements. Furthermore, the interiors and exteriors of EVs are increasingly incorporating recycled and natural fibers, offering both aesthetic appeal and environmental benefits. As urban mobility patterns evolve, lightweight and durable materials are essential for shared vehicle fleets and micro-mobility devices, ensuring longevity and efficient operation.

Enhancing Vehicle Performance and Safety Through Material Science

Sustainable materials are not solely about environmental benefits; they also contribute significantly to vehicle performance and safety. Advanced composites and lightweight metals, for instance, can reduce vehicle weight, leading to improved fuel efficiency for conventional vehicles and extended range for electric vehicles. This reduction in mass also positively impacts vehicle dynamics, including acceleration and handling. In terms of safety, ongoing engineering research focuses on developing materials that offer superior crash absorption properties while remaining environmentally responsible, ensuring occupant protection without compromising sustainability goals for modern automotive design.

The Role of Technology and Digitalization in Material Engineering

Technology and digitalization play a pivotal role in the advancement and adoption of sustainable materials in automotive engineering. Advanced simulation tools allow engineers to test material properties and performance virtually, optimizing designs before physical prototypes are created, which saves resources and reduces waste. Artificial intelligence and machine learning are being used to discover new material combinations and predict their characteristics, accelerating the development cycle. Furthermore, digital platforms enhance supply chain transparency, enabling manufacturers to verify the sustainable sourcing and ethical production of materials used in vehicle components.

Future Outlook for Sustainable Vehicle Manufacturing

The journey toward fully sustainable vehicle manufacturing is continuous, with ongoing research and development exploring new frontiers. Innovations in areas like self-healing materials, advanced recycling techniques for complex components, and further integration of renewable energy sources into manufacturing processes are anticipated. The automotive industry’s commitment to these sustainable practices is not just about compliance but also about driving innovation that benefits both consumers and the planet, shaping the future of global transport and mobility. This holistic approach, encompassing everything from material sourcing to end-of-life recycling, defines the next generation of automotive engineering.

Global Efforts in Sustainable Automotive Practices

Many automotive companies worldwide are investing heavily in research and development to integrate sustainable materials and processes. These efforts often involve collaborations with material science companies, academic institutions, and recycling specialists. The focus extends beyond the vehicle itself to the entire manufacturing ecosystem, including reducing water usage, minimizing waste, and employing renewable energy in production facilities. Such comprehensive strategies are vital for creating a truly sustainable automotive industry that aligns with global environmental objectives and consumer expectations for responsible manufacturing.